Author Archives: lpbrewer

This is the final entry in our three part series on Baltimore's water and how it relates to brewing beer. Follow the links below for information on our water sources and municipal treatment.

We’ve seen where it comes from.

So let’s talk about Baltimore’s water. What’s in it? And what does that mean for Baltimore area homebrewers?

The Baltimore Department of Public Works publishes a water quality and a water content report annually. The first report demonstrates to the public that the municipal water is safe to drink. The second report provides a mountain of data for anyone interested in a in depth look at what’s coming out of their tap. DPW monitors the water leaving each plant and records monthly data points across 23 different categories.

Using the information from the 36 months beginning in 2015 and ending in 2017, we get a picture of what Baltimore are brewers are dealing with and how it changes over time. The water leaving the Montebello and Ashburton plants is:

- remarkably similar; and,

- remarkably consistent.

Brewing Water Report

As brewers, we tend to focus on a subset of water attributes that are known to have great impact on the brewing process and finished product. The 2017 averages (all measurements are in ppm except pH) for those brewing centric categories are:

| Montebello | Ashburton | |||||

| 2017 | Low | High | 2017 | Low | High | |

| pH | 7.8 | 93% | 102% | 7.8 | 98% | 103% |

| Hardness (CaCO3) | 116 | 96% | 104% | 80 | 93% | 104% |

| Calcium (Ca) | 30 | 94% | 110% | 21 | 93% | 112% |

| Magnesium (Mg) | 9 | 94% | 107% | 6 | 97% | 106% |

| Sodium (Na) | 20 | 88% | 113% | 19 | 91% | 107% |

| Sulfate (SO4) | 17 | 85% | 122% | 13 | 91% | 135% |

| Chloride (Cl) | 53 | 91% | 123% | 42 | 98% | 103% |

Baltimore’s water is low-moderate in hardness and is relatively low in flavor ions (chlorides being the exception). Ashburton water is a touch softer than Montebello, but across the board the water content is largely the same. All told, it’s a great starting point for brewers.

Mr. Consistency

Month-to-month the water changes very little, drifting off its averages about 5% in either direction. Further, when we look year over year, the levels recorded in the data set are quite stable.

| Montebello | ||||||

| 2015 | 2016 | 2017 | 3-Year Avg | Std | % Std | |

| pH | 7.8 | 7.8 | 7.8 | 7.8 | 0.01 | 0% |

| Hardness (CaCO3) | 106 | 106 | 116 | 109.2 | 5.51 | 5% |

| Calcium (Ca) | 28 | 29 | 30 | 28.9 | 0.87 | 3% |

| Magnesium (Mg) | 8 | 9 | 9 | 8.7 | 0.37 | 4% |

| Sodium (Na) | 24 | 21 | 20 | 21.7 | 2.04 | 9% |

| Sulfate (SO4) | 20 | 16 | 17 | 17.9 | 2.08 | 12% |

| Chloride (Cl) | 64 | 52 | 53 | 56.3 | 7.08 | 13% |

| Ashburton | ||||||

| 2015 | 2016 | 2017 | 3-Year Avg | Std | % Std | |

| pH | 7.8 | 7.7 | 7.8 | 7.7 | 0.05 | 1% |

| Hardness (CaCO3) | 73 | 74 | 80 | 75.5 | 3.55 | 5% |

| Calcium (Ca) | 20 | 21 | 21 | 20.5 | 0.67 | 3% |

| Magnesium (Mg) | 5 | 6 | 6 | 5.8 | 0.32 | 6% |

| Sodium (Na) | 20 | 19 | 19 | 19.2 | 0.53 | 3% |

| Sulfate (SO4) | 12 | 12 | 13 | 12.5 | 0.90 | 7% |

| Chloride (Cl) | 43 | 41 | 42 | 42.0 | 1.04 | 2% |

So now that we know what’s in it, what does it mean?

A Tale of Two SRMs

If you’re on municipal water it doesn’t matter much which plant you are drawing from when managing your mash pH. Let’s examine the stories of two very different beers. In both examples, we’ll assume a batch sparge system with 75% efficiency & typical volumes, a target of 5 gallons into carboy, and an original specific gravity reading of 1.050; some fairly common targets and methods.

We’ll start by brewing a pale beer, say a pilsner. For our grist we’ll use 100% Pils Malt and treat our Baltimore tap water with only a Campden tablet for Chlorine. How much Acidulated malt do we need to hit a a target mash pH of 5.3?

- On the Montebello Supply we’d need 5.1%.

- On the Ashburton Supply we’d need 4.9%.

Now let’s consider the other end of the spectrum. A stout with a grain bill of 80% UK Pale, 10% C80, & 10% Roast Barley. How much Acidulated malt do we need to hit a target mash pH of 5.3?

- On the Montebello Supply we’d need 2.1%.

- On the Ashburton Supply we’d need 1.8%.

The amount of Acidulated malt required for each beer is almost identical regardless of the municipal source. Both sources are comparably low in Calcium, Sulfate, and Chloride, making it fairly straightforward to adjust the flavor ions using Gypsum (CaSO4) and Calcium Chloride (CaCl2). Additionally, if the water isn’t soft enough for your brew diluting with to a 1:1 ratio with distilled water will approximate the famous Pilsen water profile to a surprising degree.

Wrapping It Up

All considered, Baltimore’s municipal water is an asset to any local brewer and, with minimal effort, can be tweaked to a variety of profiles. Perhaps it is no wonder that Baltimore developed a rich brewing tradition rapidly after founding.

No matter how you decide to manage your water on brew day we hope this series of articles has shed a little light on the history, operation, and content of the Baltimore municipal water supply. The water here has the potential to make great beer.

Cheers and happy homebrewing!

Caveats

- Baltimore tap water contains low levels of free chlorine. There are many strategies to remove it.

- Baltimore occasionally pulls water from the Susquehanna during times of drought or excess demand. There may be intermittent periods when the water profile differs significantly from the data shown here.

- This data is taken from water leaving the filtration plants. While many of our club members report it as being consistent with water content tests from their home faucets, getting a water report from your tap is the recommended way to calibrate your brewing water calculations.

Sources:

Images:

This is the second in our three part series on Baltimore's water and how it relates to brewing beer. Follow these links for information on water sources or water content analysis.

Last week, we traveled from the beer in our glass back to the genesis of our brewing water. To the streams and rivers the City of Baltimore captures to provide a vast amount of freshwater for its citizens and industry. It is this water, from the Gunpowder Falls and Patapsco River (and occasionally the Susquehanna), that makes up the largest portion of our finished beer.

But let’s be honest, we’re not really brewing with river water are we?

Our public waterworks are a massive network of dams, pipelines, treatment processes, filtration mechanisms, and distribution systems all working in concert to deliver clean water to our homes and businesses. Put a glass of water from Loch Raven and one from the kitchen sink side-by-side and I know which one I’d rather put in my kettle. Our water undergoes an enormous transformation before it ends up at our faucet.

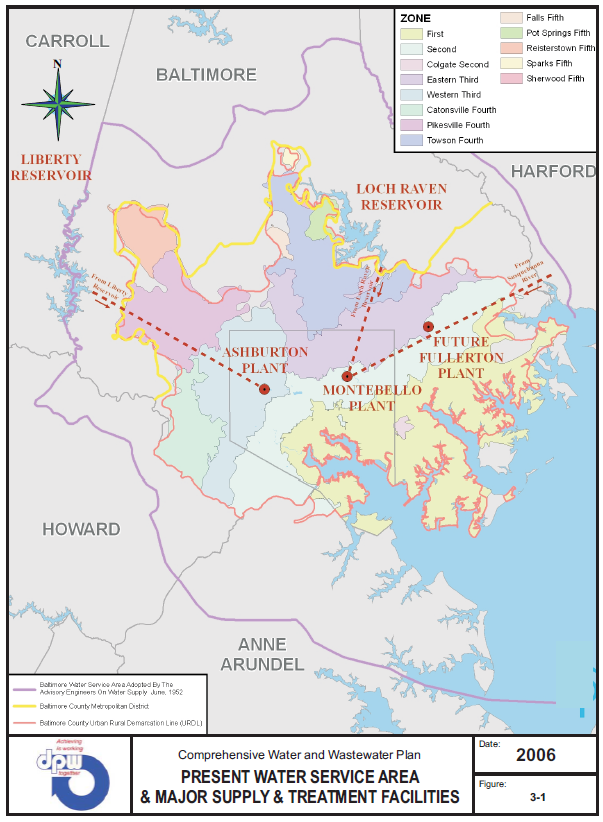

The journey starts when water from the city reservoirs is transferred via underground pipeline to one of the two filtration sites at Montebello or Ashburton. Water from the Loch Raven reservoir is gravity fed to Montebello (plants I and II) while water from the Liberty Reservoir is transferred to the Ashburton Plant. So while the plants may treat the water with the same processes they begin with different supplies.

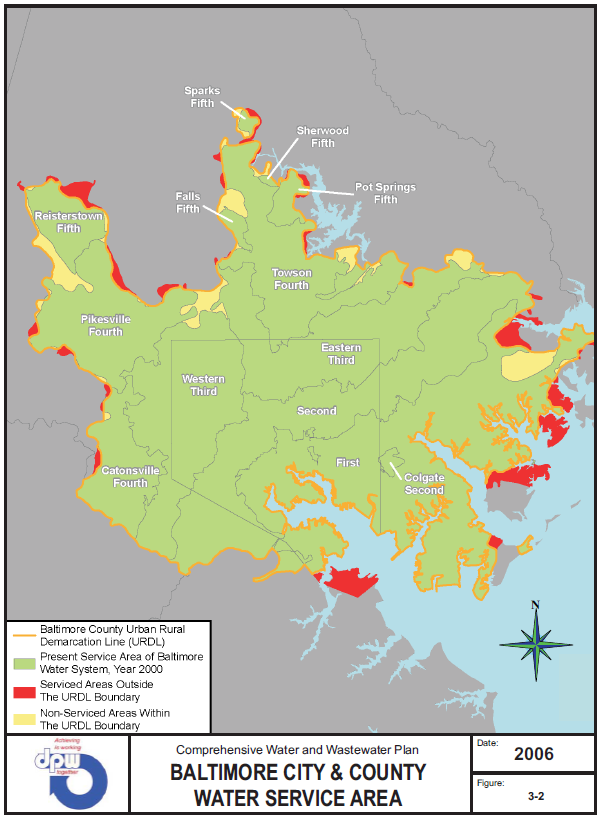

A map of the Baltimore water service area & supply & treatment facilities.

The reservoirs themselves play the first part in cleaning our water. The dams that feed the filtration plants are a great place for some particulate to settle and rough filters at the reservoir keep out large pieces of debris.

Arriving at one of the treatment plants, the water is subjected to Pre-Chlorination. Chlorine kills bacteria, protozoa, and viruses as well as prevents the growth of algae during the treatment process. The city adds enough of the chemical at the start of the process to target a residual level of 1 ppm chlorine in the distribution network. This level is necessary to prevent any regrowth on route to customers.

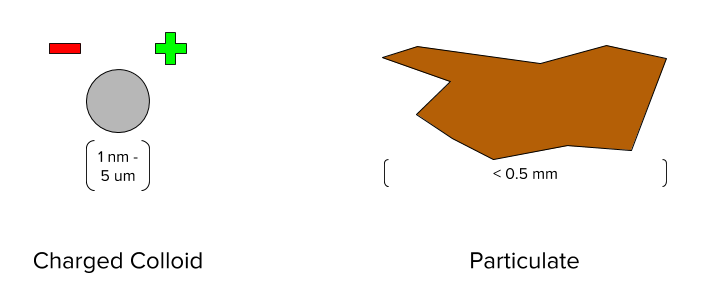

After this preliminary chemical treatment the water is still full of suspended impurities. What are these things and why are the suspended? The impurities are charged colloids and very light particulate. Animal waste, air pollution, and surface runoff are some of the chief contributors of this matter that refuses to sink either because of its charge or its density.

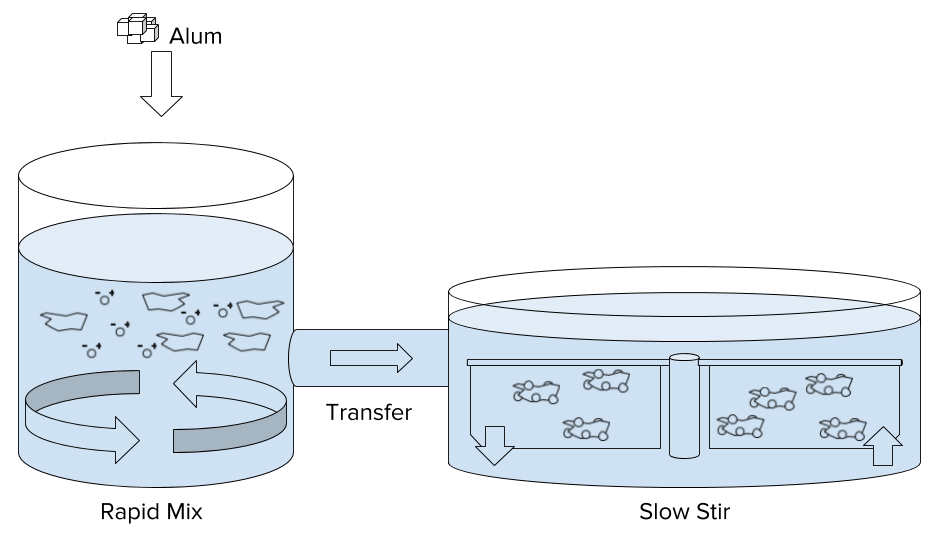

Fortunately, there are methods to encourage the particles to drop out of our water. This step is Coagulation & Flocculation. Aluminum Sulfate (alum) is added to the water which is then rapidly mixed. The solution is transferred into large tanks with slowly rotating paddles that encourage the alum and the particulate into contact. The particulate clumps together and the clumps continue to combine as they encounter each other.

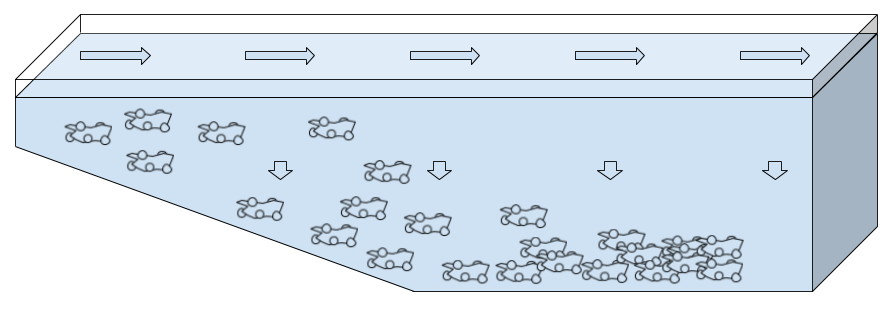

The impurities are now heavy enough to drop out of the water during the next process, Sedimentation. The water is transferred into a set of long tanks where is slowly makes its way from one end to the other. This lazy journey allows the flocculated material to fall to the bottom of the tank just like yeast groups together and drops to the bottom of our carboys as fermentation completes. Water is drawn off the top of the tank, leaving much cleaner than it entered, and the debris is periodically scrapped from the bottom of the sedimentation tanks.

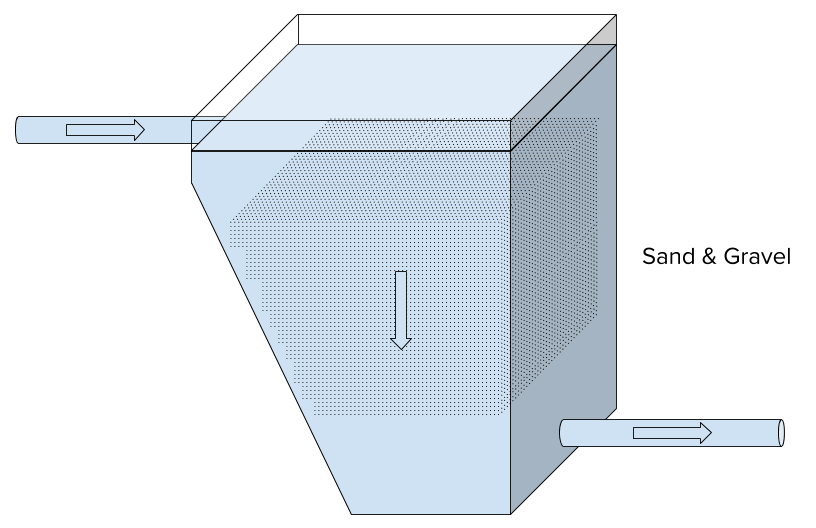

The water is now ready for its last mechanical cleaning process, Filtration. What’s happening here isn’t really much different than what happens when you fill up a filtered water pitcher. The water enters the top and is forced through a bed of sand and gravel, stripping out small particles and other impurities. Clean water exits the system from the bottom and is pumped to holding tanks to undergo final adjustments. Each plant contains a bank of filters which are backwashed on a rotating schedule to clean the filter media and ensure uninterrupted service.

Baltimore City performs three post-filtration adjustments before the water enters the city distribution network. Fluoride is added to the level of 0.7 ppm, Chlorine is added (if needed) to reach a level between 0.2 & 1 ppm, and the pH of the water is raised to 8 using Calcium Oxide (lime). These final adjustments promote dental health, ensure the treated water remains clean as it travels for delivery, and protect against leeching from pipes in the distribution system.

Depending on where your home or business is located in the city you’ll find yourself inside one of Baltimore Department of Public Works many distribution zones.

A map of the Baltimore municipal water zones.

Water from Montebello and Ashburton serves zones 1 & 2 via gravity while being pumped to the others. The cleaned and treated water ends up in taps all over Baltimore City and parts of Anne Arundel, Baltimore, Carroll, Harford, & Howard counties. DPW tests and publishes reports on the water quality & content as it leaves the plants and samples water from taps all over its network to monitor the integrity of the city supply.

So enough already! Baltimore’s waterworks are certainly impressive. A lot of effort goes into the capture, cleaning, and delivering our drinking water. As Baltimore area brewers we’re plenty interested to see what’s in it.

Up Next: Baltimore's Water: The Goods!

This is the first in our three part series on Baltimore's water and how it relates to brewing beer. Follow these links for information on municipal treatment or water content analysis.

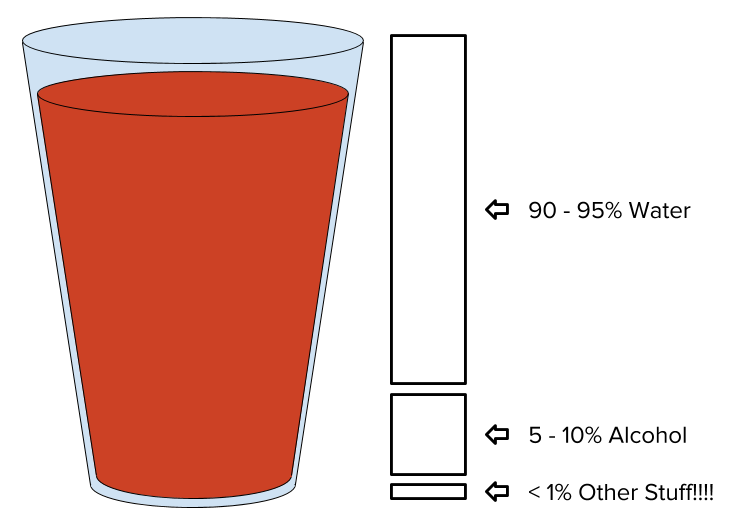

Beer! What is it?

As brewers, we often think of our beers as a recipe: a combination of malts & sugars, hops, yeast, and other flavorings. We talk of phenols, esters, and aromatic compounds that play with our grain bill to produce finished beverages. Our beers can be barrel aged, fruited, dosed with brettanomyces or finished with tinctures of cocoa & vanilla. Yet, when we break a prototypical beer into some very basic categories one item dominates.

Water. Plain. Simple. H2O.

It’s fair to say the other parts of beer add strong flavors and aromas to the drink, driving the character of our finished homebrew. Still, no matter how we choose to craft our recipe and handle the production all those ingredients and processes must sit upon a canvas of water.

The water you brew with has a measurable effect on your final product. It drives interactions in the mash (pH) & boil (break, hop utilization) and affects flocculation & other cold-side processes. It contains flavor ions that contribute character (calcium, sodium, magnesium, sulfates, and chlorides) and shape the profile of the beer.

So what does that all mean to us as homebrewers? There is a boatload of literature and a heap of anecdotes detailing how water affects beer. Baltibrew even had a QC technician from a local brewery come out to give a talk on his philosophy regarding water treatment. For the modern homebrewer information and opinions on how to handle your water abound.

So what about Baltimore's water? It turns out Baltimore water has a reputation as great brewing water!

Let’s dig a little deeper into this aquatic topic. Where does this water come from? How does it get to our faucets? And what’s in it, anyway?

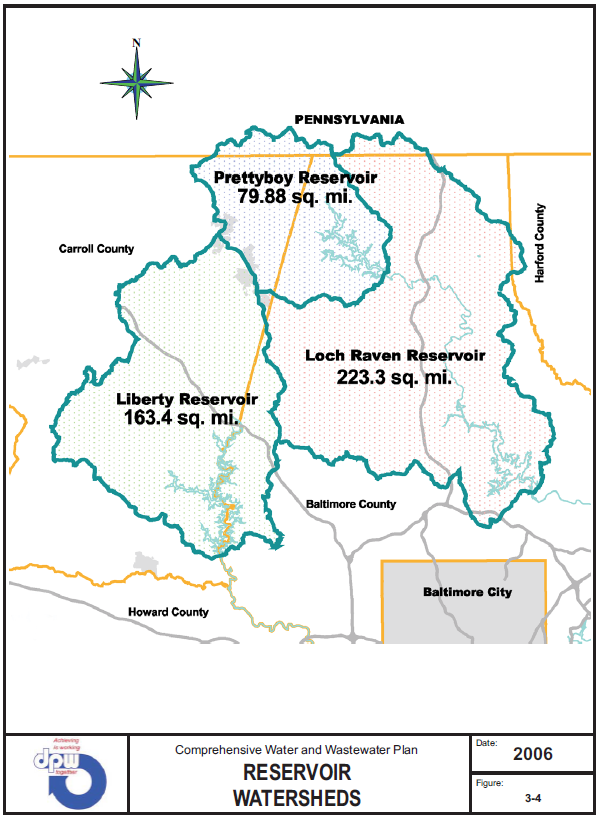

The Baltimore municipal waterworks draw water from three sources, all of which are surface water. The big name in the mix is Loch Raven Reservoir.

Loch Raven Reservoir and dam. It provides drinking water for the City of Baltimore and most of Baltimore County, Maryland.

Located just north of the city, Loch Raven Reservoir and the upstream Prettyboy Dam impound the waters of the Gunpowder Falls. Prettyboy’s function is to keep the level in Loch Raven constant, important because this water is fed to treatment plants via gravity. The two dam system ensures there is enough pressure on the water for it to make the trip via underground pipeline for treatment at one of Baltimore’s filtration plants.

Next up, Liberty Reservoir.

Liberty Reservoir Dam, Baltimore County and Carroll County, Maryland

Located to the northwest of the city this dam holds water from the Upper Branch of the Patapsco River. The combined watersheds of these three reservoirs pull water from the north & west of the city and extend as far as southern Pennsylvania.

A map of the Baltimore reservoir watersheds. (2006)

Finally, a pipeline arrives from the northeast that can pump water south to Baltimore from the Susquehanna River. Currently, the Department of Public Works only draw from this source during periods of high demand or drought. Projected growth of the region forecasts the need to pull water from the Susquehanna on a regular basis by 2025. These sources hold 86 billion gallons of fresh water for city and parts of the surrounding counties. They represent over a century's worth of public works projects to secure a quality and consistent water supply for the city.

The history of Baltimore's public water supply goes even further into the past and features a name not typically associated with clean, tasty water. The city's first successful water distribution system pulled from the pristine, picturesque...Jones Falls.

A screen placed across Jones Falls traps trash and keeps it out of Baltimore harbor. Although not foolproof-a heavy rain can break the screen-it is effective when cleaned regularly.

Over 200 years ago it looked a bit different (and modern restoration efforts of the Jones are ongoing).

Cut and bridge on the railroad at Jones Falls, Baltimore.

After several failed legislative attempts to create a public waterworks (starting in 1797) a stock company was formed in the early 1800s that impounded the Jones at Calvert & Center Streets. This company improved many aspects of its water system and was eventually sold to the city in 1854 for the sum of $1.35M. Public expansions of the system continued.

The Druid Hill Reservoir was completed in 1873. The Gunpowder Falls was captured in 1881 with Loch Raven Dam completed in 1915. In response to public health concerns the city began chlorination of its supply in 1910. The Montebello Filtration Plants (I and II) went online in 1915 & 1928. To keep up with demand the Liberty Dam was completed in 1954 and the Ashburton Filtration Plant began its operation in 1956. The system now produces 360M gallons of drinking water every day to meet the needs of its residents and business, a true feat of modern engineering.

As Baltimore area homebrewers if you start your brew day by opening the faucet to fill a kettle these are the waters you pull from. Every time we crack a homebrew it is the end of a long journey down the Gunpowder Falls & Patapsco Rivers and through a public water system designed & built over hundreds of years. A journey that passes through our recipes, our kettles & carboys, and ends right in our glass.

Cheers and Happy Brewing!

Next up: Baltimore's Water: The Journey!

Sources:

Images:

Baltibrew General Meeting

May 17, 2018 @ Jon's House

-

Introductions

-

Guild Update - Kris

- There are lots of guild events coming up, please check the calendar and listserv for updates. Minutes from the meeting are available for review. (Guild Minutes May 2018)

-

Bylaw Revisions - Status Update

- An e-board is meeting next Tuesday. The bylaw changes will be on the agenda for that meeting. More to come.

-

Discussion of Baltibrew Events

- Brubakes Recap

What a great event! Thank you to all the contestants and attendees. Paul from De Kleine Duivel is be interested in hosting again next year with an increased number of tickets. Attendance this year was about 40-50. - Brewtherville Big Brew Recap

Greg and Christoph dropped in on Brewtherville’s event. BC Brewery looks great and the beer is tasty. They have filled 18 of their 24 taps and looks to have the space to grow their operation considerably. It’s right off the light rail. Anyone who has a chance to check it out should drop by. - Sensory Classes @ Jon's

Due to scheduling conflicts the dates of the tasting panels have been moved to July 14th/15th. Reach out to Jon to sign up. The cost is $20 for one session, $35 for the pair. - Orioles Outing

July 28th is the same day as Union Collective grand opening which many members plan to attend. Since the tasting panel has been moved to July we’re going to cancel the July Orioles outing in lieu of supporting Jon’s event and the Union event. - August Bus Trip

Greg and Jacob are working up the itenary. More to come on this trip. Looking at an early August weekend. - ChiliBrew XII

Anyone interested in helping out with ChiliBrew should contact Jacob. Baltimore Beer Week has not finalized the exact week in October yet. Since we try to schedule ChiliBrew as a kickoff event we’re waiting on that decision. It will likely be October 12th but could possibly be on the 19th. Stay tuned.

- Brubakes Recap

-

Social/Event Updates - Jacob

- Brewscape @ Birroteca, May 20th

(https://www.facebook.com/events/858581900996052/) - Brew at the zoo, May 26th

(https://www.facebook.com/events/370328426782270/?event_time_id=370328446782268) - MD Guild Wheat Beer Comp and Picnic in Patapsco State Park, June 2nd (Hollofield Pavilion 301 Directions)

- MDHB Beer Education Classes

- Troubleshooting My Beer ($15), June 3rd

- Recipe Formulation ($10), July 22nd

- Annapolis Homebrew Club’s Pints for Paws Homebrew and Craft Beer festival, June 22nd

(https://www.eventbrite.com/e/4th-annual-pints-for-paws-homebrewing-and-craft-beer-festival-tickets-44105596025) - Mashout!!! August 16-19

(www.campmashout.com)

- Brewscape @ Birroteca, May 20th

-

Other New Business/Member Announcements

- Feedback Sheets for Beer Evaluation @ Meetings

The Baltibrewer survey revealed the desire for a slightly more formal procedure to request feedback on homebrew during the monthly meeting. A draft feedback sheet based on the BCJP score sheet was circulated. The general consensus was that it was too busy. A revision featuring more hedonistic categories will be available at the next meeting.

Draft Homebrew Feedback Label

Draft Homebrew Feedback Form - Iron Brewer Update

Due to waning interest in the current Iron Brewer format, the contest will change from a recurring Chopped format to more of an on-demand Bobby Flay’s Throwdown competition. The rules discussed were:- There is no scheduled Iron Brewer contest.

- Any club member may challenge the current Iron Brewer to a competition on a given style/ingredient.

- It is up to the challenger and the Iron Brewer to come to a gentlepersons agreement on when the finished beer will be judged. We can’t expect the Iron Brewer to defend challenges at every meeting.

- If the Iron Brewer repeatedly refuses to defend their title, it will be abdicated.

- Once a challenge is issued and accepted, any other club members may brew a beer for the competition.

- Judging will remain hedonistic.

- The prize remains glory and possession of the sweet Iron Brewer mug.

- The current Iron Brewer is Will.

- Feedback Sheets for Beer Evaluation @ Meetings

-

Ed Topic - Kris

- Baltibrew Yeast Capture! - Collection of captures

Many of the captures are showing mold or fungal growth. Fingers crossed that some of the recent captures show more promise. - Baltimore’s Water System!!!!

Look out for a blog post in the Education section summarizing the presentation. The tour of the Ashburton treatment plant is June 21st @ 10AM. Kris will send reminders.

- Baltibrew Yeast Capture! - Collection of captures

-

Homebrew Swap!

Baltibrew members hail from a wide range of professional backgrounds, from the service sector to the arts to engineering and finance. Among our ranks are several bonafide microbiologists. Drawing on their expertese, the club has embarked on a challenging and multi-part project for the year: we're going to try to capture, isolate, culture, and evaluate a Baltimore native brewers yeast!

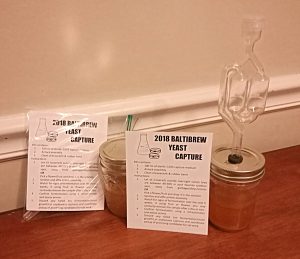

Finished capture kit for club members.

While a number of our brewers produce tasty beverages via spontaneous and mixed fermentation, there are a several challenges in an attempt to isolate a strain of yeast for brewing purposes.

- Capturing anything interesting at all!

Leaving our capture media outside doesn't guarantee we'll end up catching something that will ferment instead of just spoil. We'll be casting as large as net as we can in the hopes of finding candidate organisms.

- Capturing something that will ferment strongly on its own.

In a mixed fermentation, the processing of various sugars into ethanol and other compounds is a team game. We're looking to isolate a strain of yeast that can do the job itself and there's no assurances that the yeasts we might capture will be able to tackle the simple and more complex sugars found in wort. After we've selected candidates from our captures, we'll need to test them to see if they are up to the job.

- Capturing something that is not the Chico strain.

We're brewers and we're surrounded by brewing yeast! It's in our homebrew. It's likely floating around our houses. We'll need to take care that we don't end up "capturing" an organism that we've brought into our local environment.

- Capturing something that makes a pleasing beer.

And here's the big question. Even if we capture and isolate a yeast or yeasts that are up for the job, there's no way of telling if they'll make a pleasing product. After all, brewers yeasts has been living with humans for a very, very long time and have been heavily subjected to selection pressure. People have been knowingly (and unknowingly) changing the organism by reusing pleasing results, selecting for attenuation, floculattion, expediency, and taste. If we are successful in wrangling a pure strain of yeast that will ferment a wort of malted barley, are we lucky enough that it should make a tasty brew?

After discussing the challenges, we set about designing a simple protocol and capture media to distribute to club members at our April meeting, with the intention of collecting promising candidates at the next. We prepared and processed the capture media into 8 oz mason jars. Starting with 1 liter of distilled water and 143 grams of DME, we calibrated a pH meter and added enough lactic acid (~.5 mL) to drop the solution below 4.50 pH. The wort ended up at 1.025 SG (as converted from a Brix reading of 6.4) and a pH of 4.38. We processed 20 jars filled with 100mL of the media and half of a hop pellet each in a pressure canner at 15 PSI for 15 minutes.

Pressure canner heating up.

While the canner ran, we crafted airlocks from extra mason jar lids, rubber grommets, and S-type airlocks. The goal here was to provide a members with a simple way to limit oxygen exposure after capture, hopefully keeping some of the less favorable aerobic organisms in check.

Airlock lid for after capture.

The capture media, modified lid and airlock, clean cheesecloth, and a protocol sheet were bundled into a capture kit for members to take home. Members may choose how to conduct their capture; either directly from a biologic sample like a flower or fruit, or from the outside air itself. Admittedly, the odds are low but the fun is be in the attempt. Read more as we take our captures into the lab!

Sterile capture media.

What is Baltibrew?

A homebrew club dedicated to the discussion and exchange of fermented beverages!

Who is Baltibrew?

Great question!

Having never conducted a membership survey we decided to put a small set of questions to our brewers to get a bit of sense of who Baltibrew is. With a response rate from dues paying members of slightly over 50%, we received 23 complete surveys (1 of which only provided the written feedback). All percentages are based off the sample of actual responses. Let's dig in!

What age range do you admit to?

- 48% - 30-40

- 24% - Under 30

- 14% - 40-50

- 14% - Over 50

- 1 person admits nothing!

While homebrewing is fairly strong in the 30-40 demographic, Baltibrew skews young with 72% in the 20-40 range (the 2013 AHA Survey had 60% in the 30-50 cohort). Our membership is somewhat less skewed when compared to the results captured by the Brulosophy online survey in 2017 (65% in that under 40 cohort, 44% 30-40 & 21% <30).

Profession

- The survey categories were too granular to bucket in any meaningful way.

- Well over 50% were in the sciences, engineering, or technology related fields.

- Other industries are represented, including publishing, broadcasting, retail, manufacturing, construction, the arts, servicing, education, finance, real estate, marketing, legal.

Experience

- 50% - 5+ years

- 45% - 3-5 years

- 1 person in the 1-2 year range

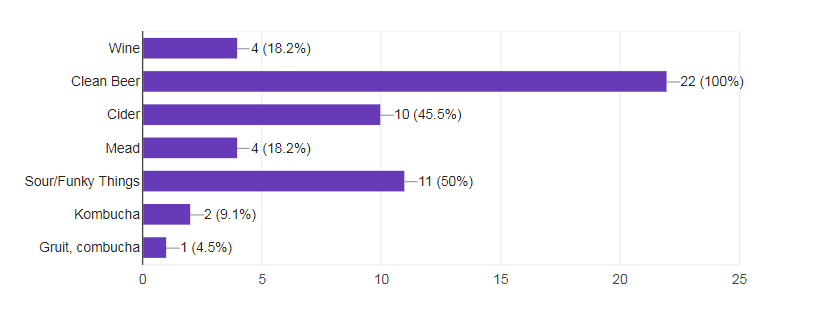

What types of fermented beverages do you produce

Half of our membership dabbles with funky brews. We have many more sour brewers (50% vs 30%) than the Brulosophy average.

How often do you brew?

- 41% - Monthly

- 18% - More than once a month

- 18% - Quarterly

- 14% - Not actively brewing

- 10% - A few times a year

What is the average volume of wort produced during a typical brew day?

- Almost 70% do 5+ gallons, 20% doing 10+ gallons, and the remainder doing 2-4 range. No 1 gallon brewers.

Which is your primary method of wort production?

- 73% are all grain brewers, the rest are evenly split between extract and partial mash. Which means we’ve more partial mash brewers than the Brulosophy survey captured.

All Grain Brewers: Which of the following best describes your methods?

- 47% us batch sparge, 30% Fly Sparge, 23% BIAB (either full volume of w/ a sparge)

What is your average pre-boil efficiency?

- 75% hit that 70-80 % efficiency, and all but 1 of the rest is above that.

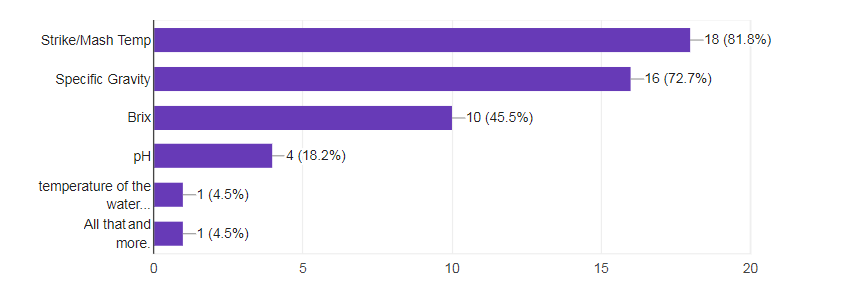

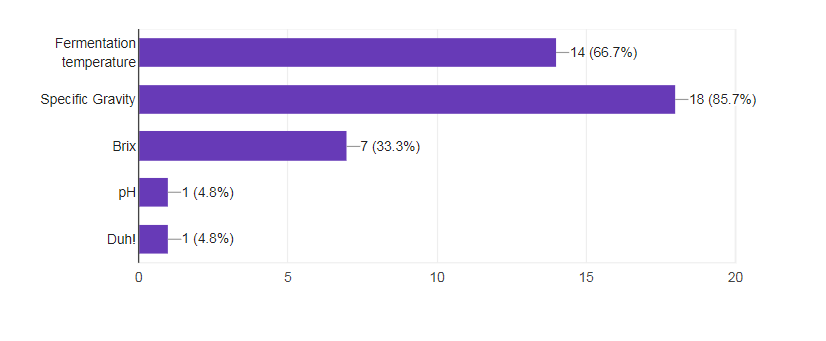

Which of following readings do you take during brew day?

Which of the following readings do you take during/after fermentation?

Which describe your use of secondary fermenters?

- 27% always use a secondary, 27% never use a secondary, and the rest use it for specific things, the most common being extended aging.

What best describes you preference for yeast?

- 40% have no attachment to dry/liquid/starters/direct pitch/rehydration/pitching from the cake.

- Among those who do have a preference, liquid yeast is king, with only 3 brewers in camp dry.

How do you most commonly package your finished products?

- Two keggers for every bottle conditioner in the club.

The prototypical Baltibrewer is….

- A mid-thirties, STEM inclined brewer who’s been at it for 5 or more years. They produce multiple types of clean and funky fermented beverages via all-grain fly or batch sparging and kegging the final product.

And lastly, why do we brew?

- Common theme in the responses is because we like to!

- Enjoy making or creating things

- Mixing art and science, experimenting

- Enjoying the company of other homebrewers/beer drinkers

- Oh course, drinking the finished product

Baltibrew General Meeting

April 19, 2018 @ Nepenthe

-

Introductions

-

Brübakes Competition Update, April 22nd @ De Kline Duvel - Jon

-

https://www.eventbrite.com/e/

baltibrew-presents-brubakes- tickets-43690968864 -

Contest is this Sunday @ 2PM. Jon will arrive a bit early to get set up. Competitors should look out for an email to coordinate. Please promote the event amongst your friends and in your social media feeds. We’ve sold 25/50 attendee tickets through the web portal so far which is pretty decent for pre-sale numbers.

-

-

Bylaw Revisions - Quick Update - Kris

-

The e-board has been working up the rest of the bylaw changes. We will discuss them at the next e-board meeting and look to bring them to the club for a vote in the next few months.

-

-

Discussion on upcoming Baltibrew Events

-

May 5th - Big Brew @ Nepenthe

-

Jude and Jacob are interested in doing a brew @ Nepenthe. Permits have not yet been acquired for the parking lot but Nepenthe will follow up. Look for an email thread to coordinate. Cairan will not be there to work logistics, so that will fall to the club.

-

-

May 6th - 2018 Big Brew w/ Brewtherville @ BC Brewery

-

Several folks are interested in dropping in on Brewtherville’s big brew event. It is a small group and they will coordinate amongst themselves.

-

-

June 9th/10th - Sensory Classes @ Jon's

-

Jon is hosting 2 days of tasting panels in June. The first day will be faults and the second will focus on barrel flavors. Each panel will consist of 15 different compounds. Cost will be set at $35 dollars for both days, $20 for one day. Seats are limited to 20 per day and the tastings run from 12-3PM. Tasters should plan to arrive 20 minutes early so the panel can begin on time.

-

-

-

Social/Event Updates - Jacob

- DC Beer Fest. April 21st (https://www.dcbeerfestival.

com/) - Bluegrass, Brew, and BBQ Festival at Red Shedman Farm Brewery. April 21st (http://redshedman.com/events/

2018-bluegrass- brew-and- bbq-festival/) - FOAM’s Battle of the Bubbles. Entry deadline is April 28. No ciders or meads. Judges and stewards wanted. May 6th (http://bob.brewcomp.com/)

- Maryland Craft Beer Festival. May 12th. (https://www.eventbrite.com/

e/maryland-craft-

beer-festival- tickets-42915664909) - Mashout!!! August 16-19 (www.campmashout.com)

- Jacob will be updating the group with additional Baltimore local beer related events including the Baltibrew bus trip in August.

- DC Beer Fest. April 21st (https://www.dcbeerfestival.

-

Other New Business/Member Announcements

- If you need to pay dues please see Greg or visit the website to pay via the paypal link.

-

Education - Kris

-

2018 Baltibrewer Survey Results!

-

Result summary in attached document. 2018 Baltibrew Survey Results

-

There was interest in providing the opportunity for more focused feedback during the homebrew swap section of meetings. We will draft a feedback form that brewers seeking comment can place on any beers they want detailed notes from others.

-

-

Baltibrew Yeast Capture! - feat. Christoph & Becky

-

The big 2018 education project is an attempt to capture and isolate a pure strain of saccharomyces from Baltimore. Kris and Christoph distributed 15 capture kits to club members. A protocol sheet was included in the kits and reviewed at the meeting. This portion of the activity centers around getting a large sampling of organisms from the area for Christoph and Becky to plate out. Please bring successful captures to the next meeting for lab work.

-

If successful isolate a good brewing yeast we will try to incorporate it in the historical Baltimore beer education project later this year.

-

-

Water Survey Collection

-

Jude, Greg, and Christoph provided water samples from Hampden, Fells Point, and Lutherville. Becky and Max will provide a sample from Riverside. Kris is probably going to coordinate a tour of one of the water processing plants for his family in the next month. He will let the group know when that is in case anyone wants to join.

-

-

-

Iron Brewer - Tea!

-

We had three entries for Iron Brewer Tea, the winner being Will’s Chai Saison!

-

Details on the next Iron Brewer competition will come at the May meeting.

-

Baltibrew General Meeting

March 15, 2018 @ Nepenthe

-

Guild Minutes - Nate

-

Guild minutes were sent out to the Baltibrew listserve.

-

The BJCP class was cancelled due to lack of interest.

-

A number of events are coming up, including the CRABs Light Rail crawl on April 8th and the VIctory Brewing Taste at Goddard Space Flight Center on March 16th (Zymurnauts).

-

MALT was happy to see so many Baltibrewers sign up for their bus trip!

-

Brubakes was plugged, there seemed to be some interest.

-

-

Discussion on upcoming Baltibrew Events

-

May 5th - 2018 Big Brew

Nepenthe is not sure if they will be hosting a Big Brew event this year, as they have not worked out their lease in the near term. Several options were proposed, including attending the brew at Maryland Homebrew or joining Brewtherville’s Big Brew. Members will reach out to the other organizations and we will pick the discussion up next month. -

July 27th - Baseball Os vs Rays Group Outing

The club decided to move this outing to July 28th as Saturdays are generally easier for most of the members. We will be looking to get a block of 30 tickets in the outfield bleachers, likely cost will be $17 dollars a seat. Options for a pre-game beer include the new Suspended Brewing in Pigtown. -

August TBD - Balitbrew Bus Brewery Trip

Jacob and Greg are getting quotes for the bus trip. There are a few possible destinations in play, including DC, Columbia, and Eastern Shore breweries. More information to follow. We will likely open up registration to guild members.

-

-

Bylaw Revisions

-

Update to Quorum Rules - The eboard suggests changing the quorum rules as follows:

-

Individuals shall be considered members of Baltibrew upon payment of dues. One is considered a member in good standing if current dues are paid in full. One is considered an active member if they have participated in at least 50% of votes from the previous calendar year. New members will be considered active upon the meeting following their initial payment of dues.

-

A quorum shall be considered the participation of a minimum of 50% of active members in good standing for a vote.

-

Changes to Baltibrew charter, bylaws, or articles will require a quorum of ⅔ of active members in good standing.

-

-

The goals for this change were to:

-

Drop the quorum requirement in the short term.

-

Encourage vote participation and provides mechanisms for the quorum requirements to rise over time.

-

Not bar any good standing member from casting a vote.

-

Prevent members from stacking a vote at the next meeting with new signups.

-

Not create an unreasonable burden on the eboard to manage.

-

-

The rest of the draft amendments will be brought before the club for comment in future months.

-

We will vote on the changes after the club has had a chance to discuss all the draft language.

-

-

Brübakes Competition Update, April 22nd @ De Kline Duvel

-

https://www.eventbrite.com/e/

baltibrew-presents-brubakes- tickets-43690968864 -

We should assume that all the competitors for this first year will be Baltibrewer and we need six.

-

Please get the word out! Jon and Nate will get the word out to other clubs via the guild and their contacts.

-

Caiti volunteered to work with Jon to get a flyer up in some local bars and breweries.

-

-

Social/Event Updates - Jacob

-

Diamondback Brewing in Locust Point releases dry stout with cacao, Friday, March 16th

-

The Baltimore Whiskey Company’s first Epoch Straight Rye Whiskey Release, March 17th (https://www.facebook.com/

events/2066954510256560/) -

Mashout!!! August 16-19, 2018 (www.campmashout.com)

-

Nepenthe’s Apples to Apples @ Blue Pit on April 15th (https://www.nepenthehomebrew.

com/products/apples-to-apples- 2018-ticket)

-

-

Other New Business/Member Announcements

-

Iron Brewer - Tea @ the April meeting!

-

-

Ed Topic - Kris

-

Meet the Ed Czar!

-

2018 Ed Topics

-

March

-

Topic - Get to know your Ed Czar

-

Activity - Baltibrewer Survey

-

-

April

-

Topic - Baltibrewer Survey Results

-

Activity - Passing out wild yeast collection jars

-

Activity - Send in Water Survey Samples

-

-

May

-

Topic - Water Survey Results

-

-

June

-

Topic - Discussion - Fault and Flavors/Post -Mortem of Jon’s Tasting Panels

-

-

July

-

Activity - Sour Hour

-

-

August

-

Activity - Baltibrew Neighborhood Yeast Tasting

-

-

September

-

Topic - Brief History of Commercial Brewing in MD

-

Activity - Historical Beer from Baltimore

-

-

October

-

Topic - TBD

-

-

November

-

Topic - Apples and Honey - How Beer and Cider are different

-

-

December - Holiday Party - No Ed Topic

-

-

Baltibrewer Survey - Watch for an email with a link to the survey.

-

-

Homebrew Swap!

Baltibrew General Meeting

February 15, 2018 @ Nepenthe

-

The 2018 Baltibrew Event Calendar

-

March 24th - MALT Bus Trip to Philly

Malt has provided a code for a discount to Guild Members. Let’s get out there and support another club’s event! Purchase tickets @ https://maltbusbalt.brownpapertickets.com/.

-

April 22nd - Brübakes Competition @ De Kline Duvel

We are looking to start a spring event for BaltiBrew. Jon is going to coordinate an event, hopefully at De Kline Duvel, in April. The idea is to pair a brewer and a baker and produce a siason and a baked good featuring the spent grain from the beer. The baked good must be 10% spent grain by weight. Looking for 6-8 competitors. It will be an Sunday afternoon event with the attendees choosing the winners. More information to come.

-

May 5th - 2018 Big Brew

Nepenthe is not sure they will be hosting a Big Brew event this year so we may need to either find another venue or join up with another club.

-

June 9th/10th - Sensory Classes @ Jon's

Jon is going to do his sensory classes again in June. This year Siebel has released some new flavor profiles specific to barrel aging which Jon will evaluate and may incorporate into the sessions. Price will be set to recoup costs and should be close to 40 dollars for both sessions. More information to follow.

-

July 27th - Baseball Os vs Rays Group Outing

Kris and Detter will coordinate a block of tickets for the Friday night Os game. We could potentially drop in on Suspended Brewing in Pigtown before the game.

-

August TBD - BalitBrew Bus Brewery Trip

Jacob/Greg will be coordinating a brewery trip with the destinations TBD. Ideas include a trip to check out the DC scene or visiting Key and some Baltimore suburb breweries. This event will be open to Guild members.

-

September 1st - BBQ and Group Brew @ Jacob's

A potluck BBQ and Brew at Jacob’s in Towson to kick off the fall season!

-

October 12th - ChiliBrew XII!!!!!!

Ciaran and Jacob will be leading the ChiliBrew charge this year. The event will be run similar to previous years.

-

November TBD based on pressings - Cider Buy/Honey Buy w/ Wootown

In the past we had sent a pretty large contingent to Wootown’s honey buy in White Hall. It’s a great event on a big farm/apiary and they have great quality and affordable honey. Additionally, our cider buy from Weber’s was a big success last year so we’re going to reciprocate by opening it up to Guild members. More details to come later in the year.

-

December 12th - Christmas/Holiday Party

A potluck in place of the monthly meeting. Business will be light and the event moved forward a week so members do not need to choose between this event and other holiday obligations.

-

-

Introduction of new attendees

-

Bylaw Revisions

-

Update to Quorum Rules

The current bylaws have set the definition of quorum high enough to where the club can no longer hold a votes. A proposal was made among in those in attendance to redefine a quorum as “any dues paying and interested member” where interest is loosely defined as “has attended a meeting, conversed on the listserve, or generally expressed interest in the club in the last several months.” The in attendance membership voted to accept this new definition. The specific language of this change will be brought before the in attendance member next month.

-

Potential Bylaws Updates

The following bylaws changes were proposed in order to simplify club business and to reflect the smaller member count. Members discussed the potential changes and each change will be formally drafted for an individual vote at future meetings.

- Remove Brewmaster position, Merge Secretary/Scribe Duties into Meeting Czar

- Elections are only for positions where member wants to step down or is challenged

- Move elections to fit with Jan-Dec timeframe (announce in Oct, vote in November)

- Voting Procedures - Allow two weeks for proxy votes via email and tally votes at meeting; Reduce online balloting

- Quarterly E-board Planning Meetings

-

-

Acceptance of New Officers/Thank You to Outbound Officers!

- The in attendance members voted to accept the slate nominees as the 2018 officer core.

- Brewmaster - Jon Blair

- Chilibrew Task Czar - Ciaran Ussher

- Education Czar - Kristofer Quinn

- Monthly Meeting Czar - Vacant

- Free State Homebrew Guild Representative - Nate Remlinger

- Quartermaster - Vacant

- Secretary - Vacant

- Social Secretary - Jacob Wolf

- Treasurer - Gregory Schwender

- Website Coordinator - Jude Finnell

-

BalitBrew Website Update - Jude

- Watch out for changes to the website. We will be sunsetting some unused sections and generally cleaning things up. Event planning and chatter will move to the Facebook page.

-

Social Update - Detter

- Max's Belgian Beer Fest (2/16 - 2/19) - Friday is the big Belgian Day, Saturday morning/afternoon is a focus on Stillwater in upstairs, and Monday is American Sours

- Union Pinewood Derby - This Sunday 2/18

-

Other New Business/Member Announcements

- BaltiBrew Shirt and Glassware are still available for purchase! Talk to Nick and Christoph if you are interested.

- Jon is looking for a travel buddy for the Beeradvocate Belgian Beer Fest in Boston in June. Ping him for more information or to coordinate travel. Links for tickets can be found on the Beeradvocate site.

-

Homebrew Swap!

This post will serve as the vote for the 2018 BaltiBrew officers. The following members have been nominated:

- Brewmaster - Jon Blair

- Chilibrew Task Czar - Ciaran Ussher

- Education Czar - Kristofer Quinn

- Monthly Meeting Czar - Vacant

- Free State Homebrew Guild Representative - Nate Remlinger

- Quartermaster - Vacant

- Secretary - Vacant

- Social Secretary - Jacob Wolf

- Treasurer - Gregory Schwender

- Website Coordinator - Jude Finnell

Do you accept the list of 2018 Officer candidates?

- Yes (100%, 10 Votes)

- No (0%, 0 Votes)

Total Voters: 10